Writing on behalf of The Tile Association, TTA Technical Committee Member and Group Technical Manager at Domus Group Colin Stanyard discusses the popularity of porcelain large format tiles and key considerations for installing them in line with British Standards.

Large format porcelain tiles and panels are the trend that continues, quite literally, to grow. As the popularity of seamless finishes increases, the reduced joints and grout lines offered by large format porcelain tiles and panels are a design feature in demand to create uninterrupted interiors that feel modern and spacious. Blending style with functionality, large format porcelain tiles and panels enhance key benefits of using ceramic materials, from lasting durability to easy maintenance.

Able to be used on either walls or floors and fabricated into sinks, worktops and other custom features, large format porcelain panels offer flexible and continuous finishes that enable harmonious bespoke designs. This suits the emerging fashion of tile drenching, in which one tile design is used continuously throughout an interior space across walls, floors and often fixtures for dramatic effect. The market now features a wide choice of patterns and colours, including hyper-realistic wood, concrete and stone effects. In fact, Barbour ABI’s 2025–2029 UK Floor and Wall Tiles Market Report reflects that innovations in large-format thin porcelain tiles offering ‘natural look’ finishes have propelled demand.

Not only does this variety unleash high-end creative designs, it also means that for a successful installation, proper planning is more crucial than ever. Vital logistics considerations range from tile size and pattern to how and where the tiles will be cut and transported. Narrow floorplans and access points may impact maximum tile size and installation steps.

While not all large format tiles are made of porcelain, it is the most popular choice of material for large format slabs because it is made from refined clay and fired at extremely high temperatures, making it denser and harder than standard ceramic. As a result, it is stronger and better equipped for resisting stresses and strains in service, which is especially important for large format tiles.

Like all ceramic tiles, porcelain large format tiles and panels offer reassured safety as a non-combustible, hygienic and non-porous material. This makes them a popular choice throughout kitchens, bathrooms and commercial interiors and external ventilated facades using specialised mechanical fixing systems. The continuous surface of large format porcelain flooring provides a spacious, endless feeling, available in anti-slip finishes where required e.g. in showers. Porcelain tiles are an excellent conductor of heat, which makes them ideally suited to an underfloor heating (UFH) system, further enhancing the feeling of luxury and contentment.

Thicknesses of 10 or 12 mm would generally be selected for more heavy-duty requirements, but the important criteria are a strong, stable substrate and correct adhesive application. Thinner tiles are lighter but more vulnerable to damage during handling so proper support is essential. Large format tiles can be handled and transported using purpose designed frames and suction cups, and ‘A’ frames should be utilised to prevent flexing during storage/adhesive application. Incorrect handling risks microfractures that may not be visible at first but can cause long-term performance issues. Cutting should always be performed using purpose designed equipment and tiles should be supported on purpose designed workbenches. For cutting holes, niches, plunge cuts, etc., diamond-tip tools should be used. For complex cuts, wet cutting is essential.

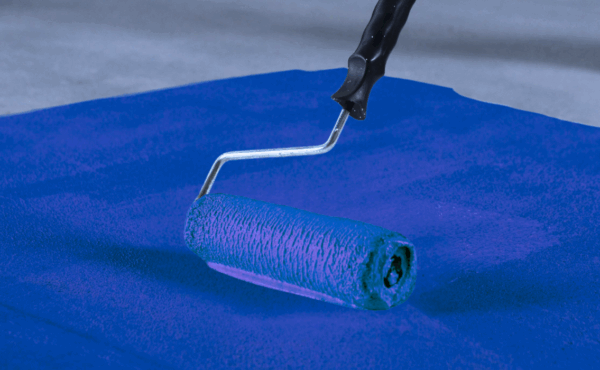

According to codes of practice, tiles, large format tiles and panels should be laid to a minimum surface regularity of SR1. Large format panels require perfectly flat substrate surfaces, as they cannot be adjusted by varying adhesive thickness in the same way smaller tiles sometimes can, which generally means a tolerance tighter than SR1. Levelling compounds, smoothing compounds or tile backer boards will almost always be required to achieve the necessary flatness.

To ensure a good bond and coverage behind the panels, the adhesive must be applied to both the substrate and the back of the tile or panel. Comb the adhesive in parallel lines on both surfaces and ensure that the ribs are in the same direction on both surfaces. For thinner tiles, lightweight adhesives are recommended to reduce overall load, especially when lifting into position. A deformable adhesive, either minimum class C2 S1 or S2, according to SB EN 12004-1, is recommended when fixing porcelain panels. Always follow manufacturer’s guidelines.

While large format porcelain tiles and panels require more consideration at the installation stage, when properly installed they offer easy maintenance in the long run. Their even, uninterrupted and hardwearing surfaces deliver lasting, aesthetically pleasing finishes that are easier to clean and maintain. For this reason, the increase in popularity of large format panels shows no sign of slowing anytime soon, especially when the panels are fabricated to create matching furniture pieces such as vanity units, modern sinks, kitchen worktops, and tables.

The Tile Association shares free tiling tips in The Tiling Guide, a handbook with practical information on key installation issues available at www.tiles.org.uk/tiling-guide/, and on TTA’s YouTube Channel at www.youtube.com/@TheTileAssociation_. Further information is available for purchase in TTA’s Technical Publications. TTA members also benefit from unlimited technical advice and support.